Your No1 source for Latest Entrance Exams, Admission info

The program includes routine inspections, repairs, and replacements of worn or damaged parts. Analyzing internal failure costs identifies problem areas in processes for future corrective action. By measuring quality costs, companies can determine exactly how much money is being lost to rework, scrap, returns, and other quality issues. External failure costs occur when defects are identified after the product has been delivered, leading to warranty claims, returns, and loss of customer trust. Toyota has earned a reputation as a leader in manufacturing durable and reliable SUVs.

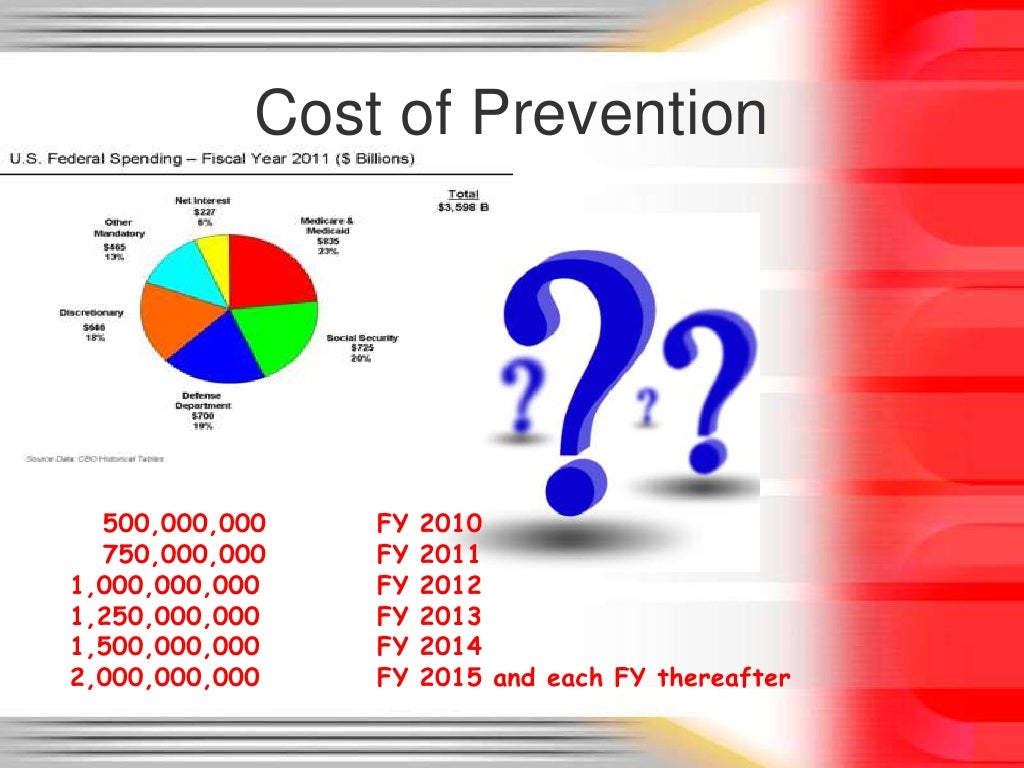

Additionally, prevention costs can help to reduce overall costs by minimizing the need for rework, repairs, and other corrective actions. This can save businesses significant amounts of money in the long run, as it is much cheaper to prevent a problem from occurring in the first place than fixing it after the fact. Monitoring external failure costs is imperative as it directly impacts customer satisfaction levels and brand reputation.

This department is responsible for ensuring that products are designed to be efficient, reliable, and easy to use. They may be responsible for conducting research and development activities to identify potential design flaws and make necessary changes. Appraisal costs, on the other hand, are expenses related to evaluating and measuring the quality of products or services to ensure they meet established standards. These costs are incur after the production or service delivery process to detect and correct defects before they reach the customer. Appraisal costs are considered necessary to maintain quality control and verify that products or services meet required specifications. As an example of preventive costs, a company invests in training programs for the operators of its production machinery, to ensure that they understand how to manufacture parts correctly.

Prevention costs can also help reduce the cost of production and improve profitability. Companies can measure the cost savings achieved by comparing the total investment in prevention to the cost of quality before and after implementing prevention measures. Implementing prevention costs requires resources such as time, personnel, and finances.

This can help ensure products are manufactured to a high-quality standard, improving customer satisfaction and loyalty. The prevention cost refers to the costs incurred by companies to reduce errors in the production process. While some industries have strict protocols for maintaining quality standards, many companies self-implement such measures.

They can guide best practices for implementing prevention costs and help develop and implement quality control measures. Additionally, we will examine the challenges that companies face when implementing prevention costs and provide best practices for successful implementation. Furthermore, we will explore the impact of technology on prevention costs and their effect on employee productivity and morale. Finally, we will discuss when businesses should review and revise their prevention cost strategies. As initiatives like Six Sigma and ISO 9001 reduce errors, organizations can quantify savings in prevention, appraisal, and failure costs. Comparing the current cost of poor quality metrics to past performance illustrates tangible financial gains from quality programs.

Additionally, if the defects or errors result in legal consequences, a company may face fines and legal fees, which can be a significant financial burden. When a company produces high-quality products and services, it can contribute to the well-being and safety of the community. For instance, investing in prevention costs in the healthcare industry can improve patient outcomes and reduce healthcare costs, positively impacting society’s overall health.

Cost of quality can also be classified as visible and invisible costs (also called the hidden costs). There’s a lot to consider so it might be tempting to oversimplify or overcomplicate. While keeping things simple is good (particularly at the beginning—you can always add complexity to your model later), oversimplification can lead to missed costs and trends.

By tracking changes in customer satisfaction before and after implementing prevention measures, companies can gauge the impact of their investments on customer perception and loyalty. Employee feedback can be a valuable source of washington d c tax preparation information on the effectiveness of prevention costs. Companies can conduct surveys to gather input from employees on how prevention costs have impacted their work and the overall quality of the products and services offered.

Leave a Reply